To ensure stable printer operation and prevent excessive wear, abnormal noises, or jamming during operation, regular maintenance of the linear guides is crucial.

¶ Maintenance Schedule and Procedures

Every 1,000 printing hours or when print offset occurs before reaching 1,000 hours:

1.Clean the X, Y, and Z-axis linear shafts with a dust-free cloth or paper. After cleaning, apply WD-40 high-performance silicone lubricant evenly.

2.After cleaning the Z-axis lead screw, please apply the provided or a suitable lubricant evenly.

¶ Maintenance Tools

- Dust-free cloth

- 2.0mm Allen wrench,

- WD-40 high-performance silicone lubricant

¶ Detailed Maintenance Steps for the X-axis Linear Guide

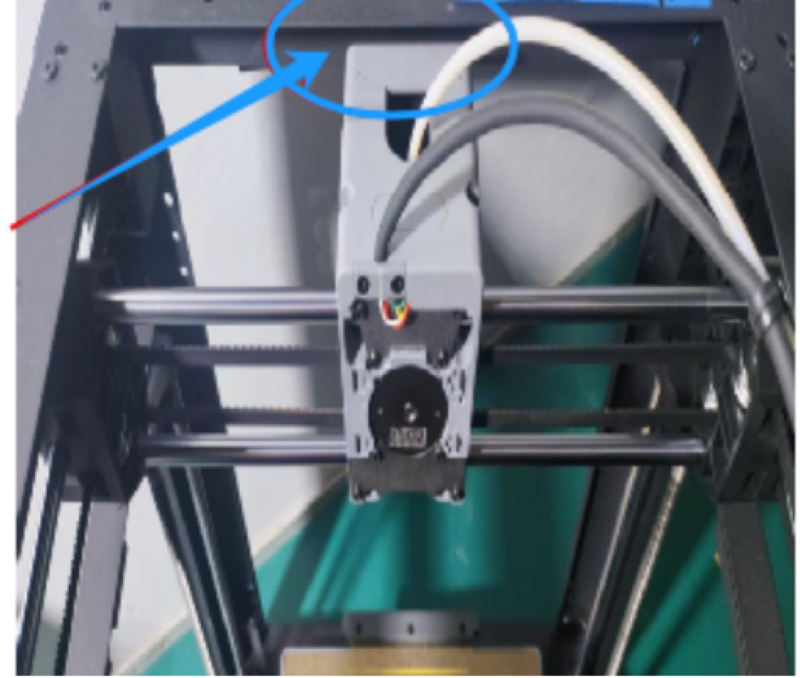

1. Place the printer on a table with the back facing you. Manually slide the X-axis extruder to the center and move it to the frontmost position. Ensure the extruder does not touch the sheet metal top cover.

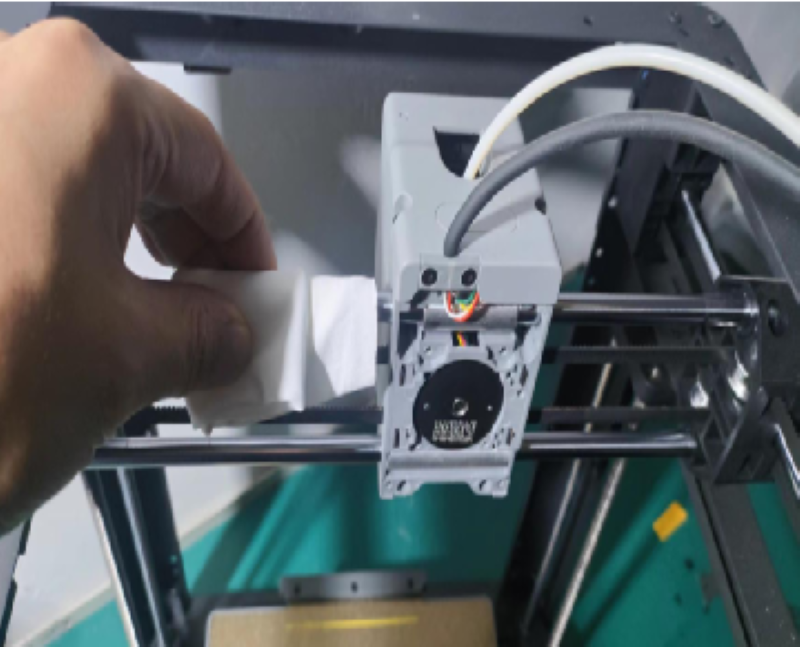

2. Use a 2.0mm Allen wrench to remove the top and bottom covers of the extruder mounting bracket.

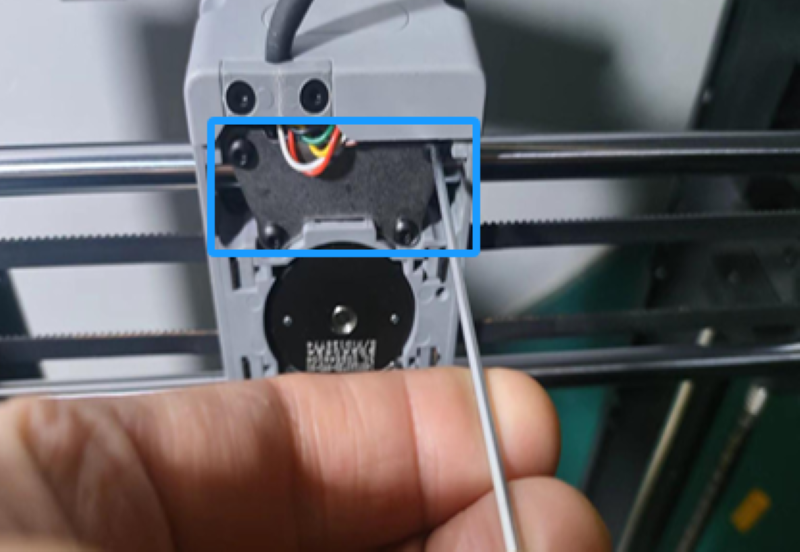

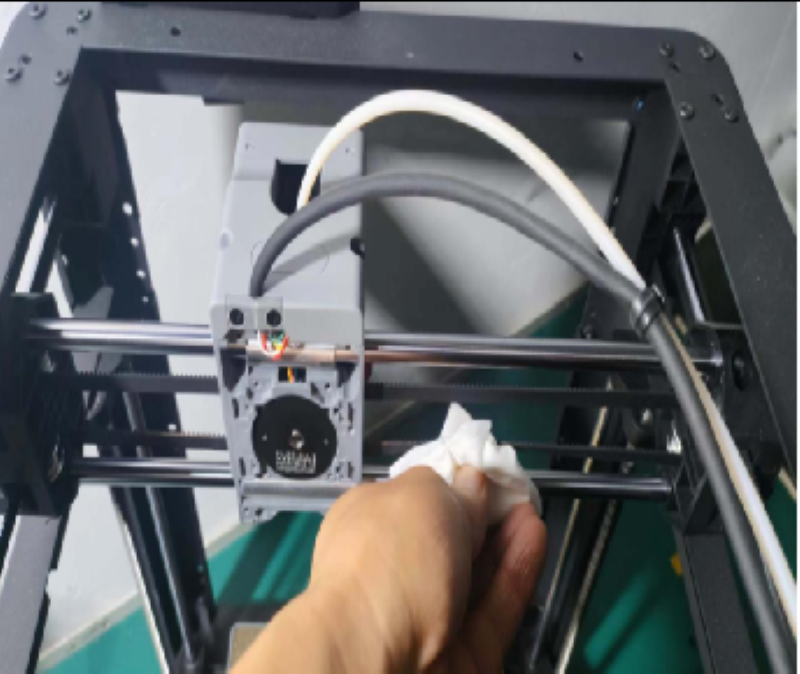

3. As shown below, use a dust-free cloth to clean both sides of the upper and lower sleeves, and then clean the surface of the X-axis guide rail.

4. Manually slide the extruder back and forth 5 times. Ensure the sliding range does not exceed the left and right edges of the bed during each slide. After each slide, use a dust-free cloth to wipe the upper and lower surfaces of the X-axis guide rail.

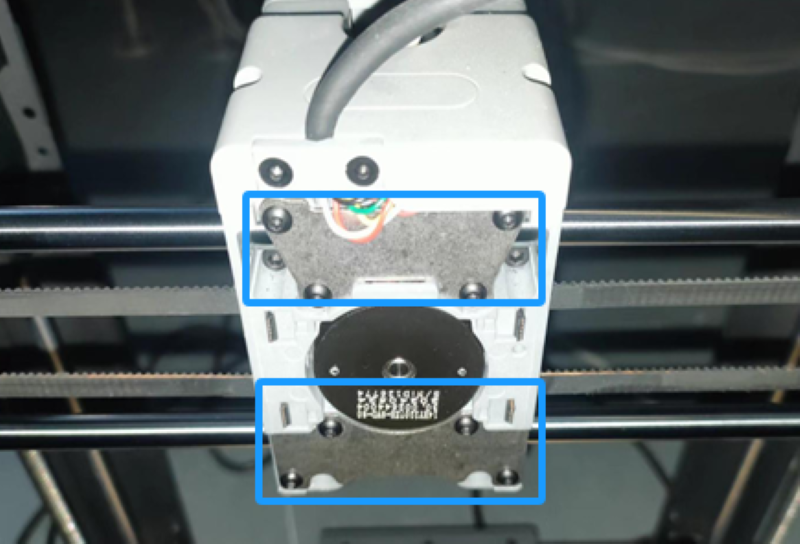

5. After cleaning, apply a small amount of WD-40 lubricant to both sides of the upper and lower sleeves. Be careful not to spray onto the print bed. If any WD-40 lubricant lands on the bed, clean it with alcohol.

6. Manually slide the extruder back and forth 5 times. Ensure the sliding range does not exceed the left and right edges of the bed during each slide. After each slide, use a dust-free cloth to wipe the upper and lower surfaces of the X-axis guide rail.

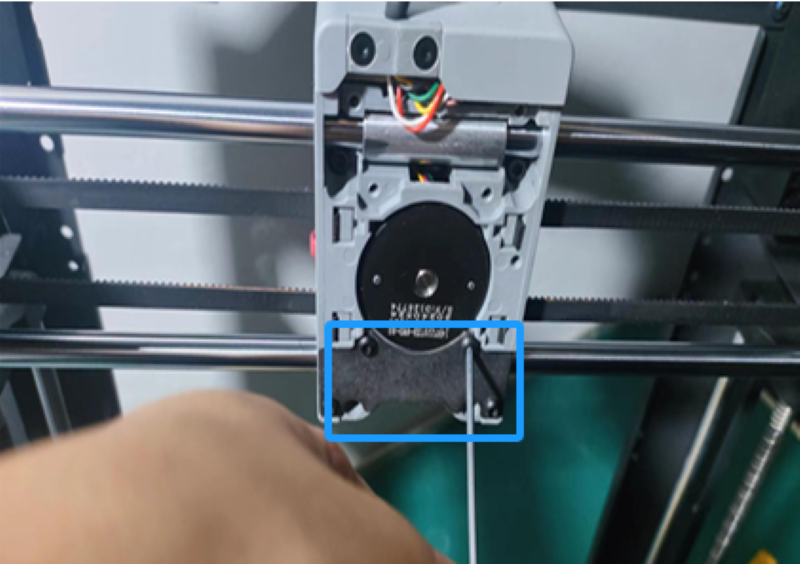

7. Then apply WD-40 lubricant onto a clean dust-free cloth as shown.

8. Use the lubricant-coated cloth to wipe the upper and lower surfaces of the guide rail evenly as shown.

9. After wiping, manually slide the extruder back and forth 5 times. Ensure the sliding range does not exceed the left and right edges of the bed during each slide. After each slide, use a dust-free cloth to wipe the upper and lower surfaces of the X-axis guide rail.

10. Once cleaning and lubrication are completed, reinstall the top and bottom covers of the extruder mounting bracket using a 2.0mm Allen wrench.

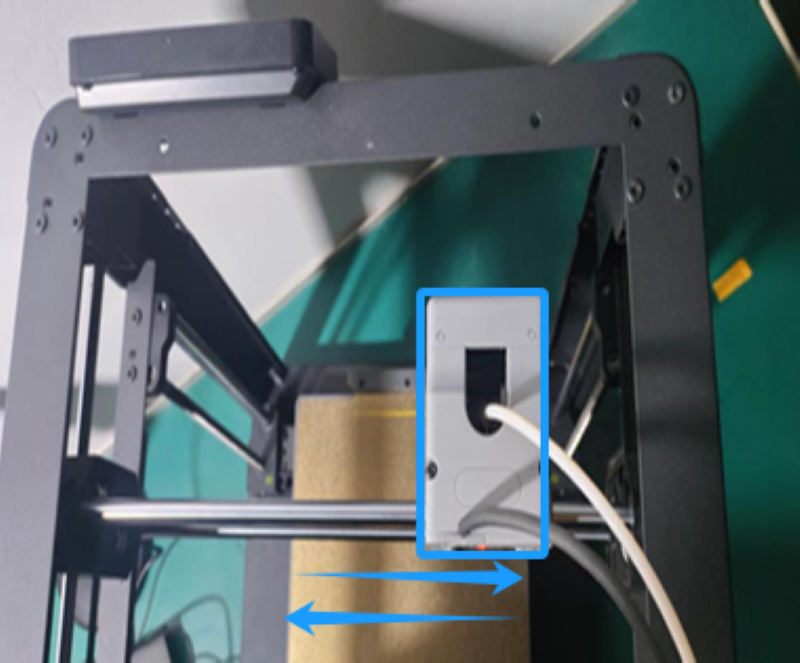

11. Clean and lubricate the Y and Z-axis linear guides following the same procedures as for the X-axis. For the Y and Z-axis bearings, directly apply WD-40 lubricant onto both sides of the bearings to clean any dirt.

¶ Detailed Maintenance Steps for the Z-axis lead screw

detailed maintenance steps for Z-axis lead screw refer to troubleshooting(2.Layer Lines on 3D Prints).