¶ Filament Change

Guider 3 Ultra supports various filaments, which can be changed according to your needs. The steps for filament change are as follows:

Note:

1. When switching from a high-temperature material to a low-temperature material, extruder cleaning is required.

2. Please clean the extruder before and after using PETG material. For details, please refer to the extruder cleaning section.

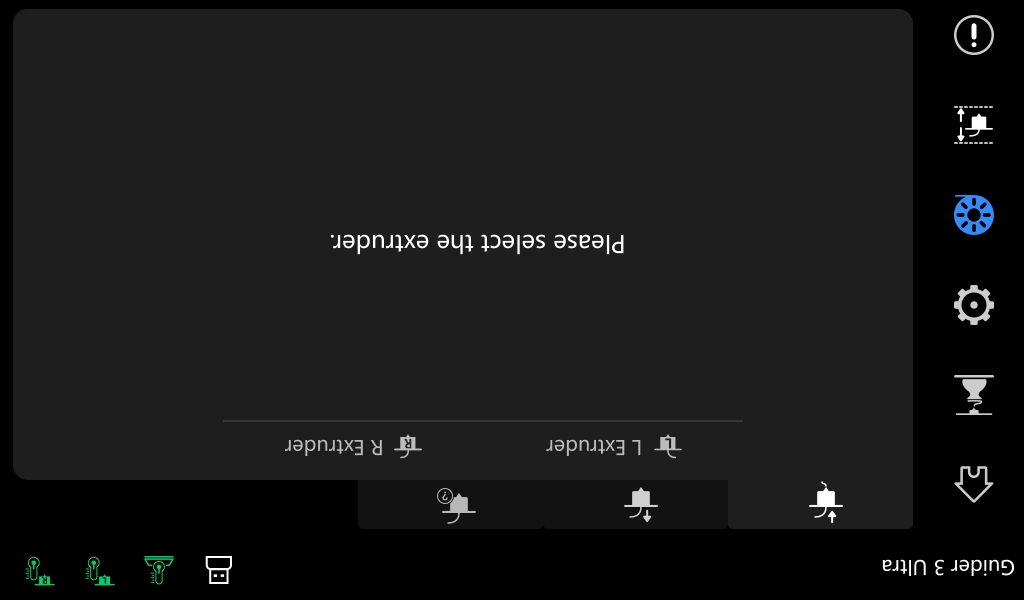

1. Select [![]() ] on the main interface to enter the filament loading and unloading interface as shown below.

] on the main interface to enter the filament loading and unloading interface as shown below.

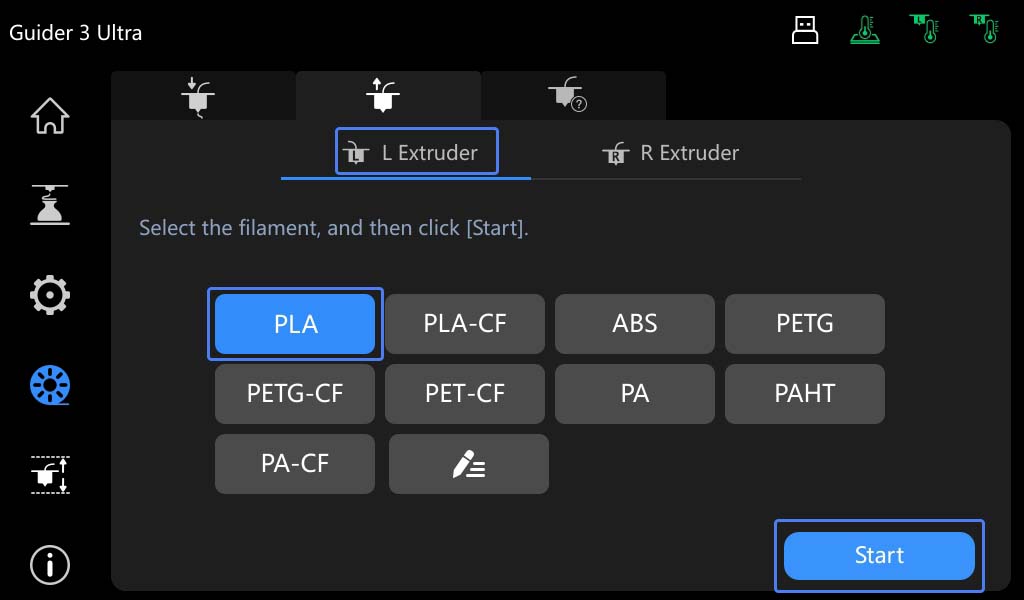

2. Click [![]() ], select the extruder for filament change (here, the left extruder is selected for example), then select the currently loaded filament (here, select [PLA]), and click [Start].

], select the extruder for filament change (here, the left extruder is selected for example), then select the currently loaded filament (here, select [PLA]), and click [Start].

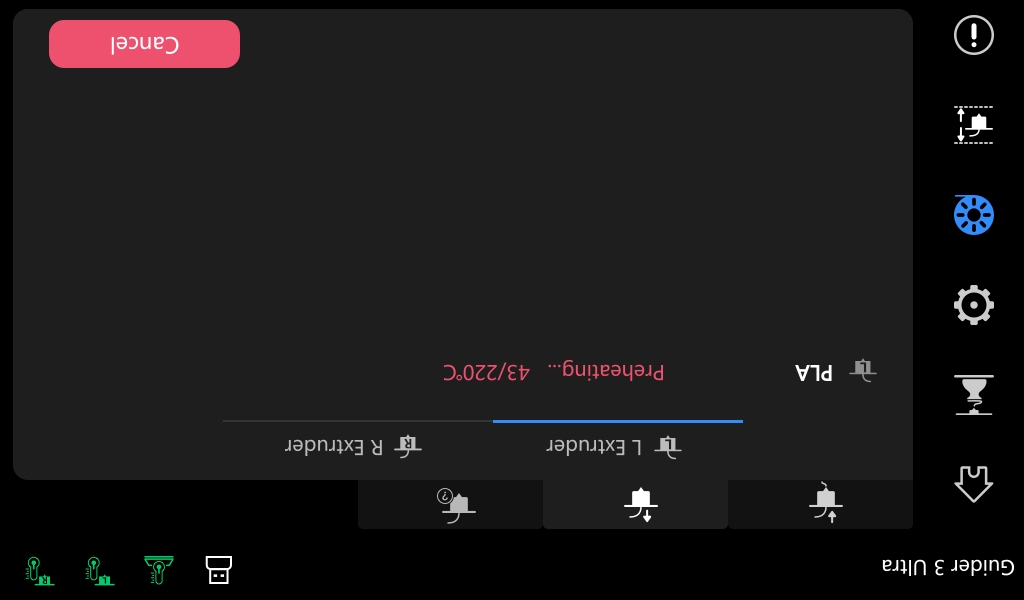

3. After clicking [Start], the printer starts heating up. The screen will display as shown below.

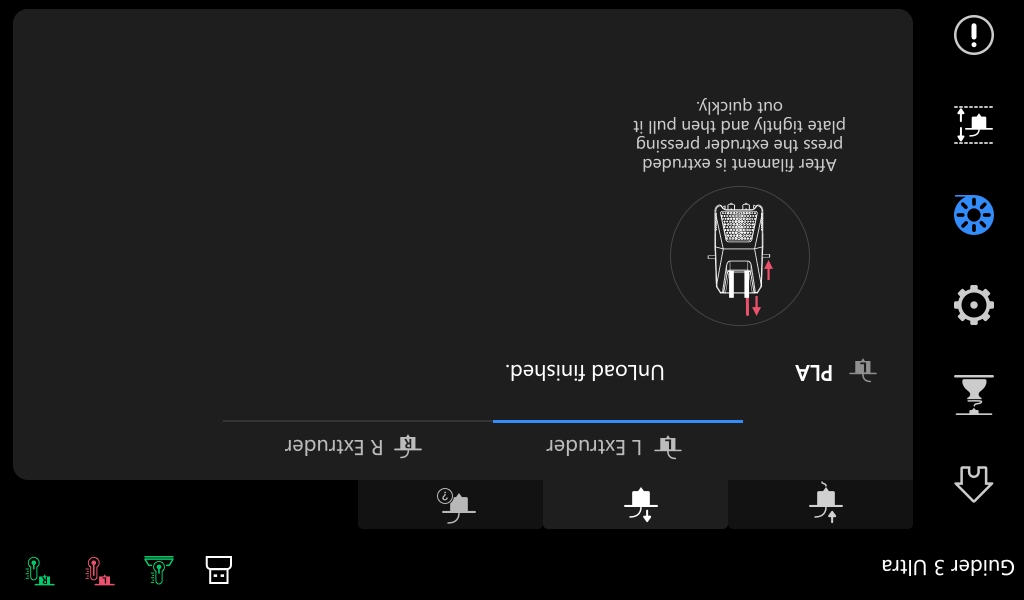

4. Once it reaches the target temperature, the printer starts extruding filament. When filament flows out of the nozzle, press down the handle with one hand and quickly pull out the filament with the other hand following the printer's prompts.

5. Open the corresponding filament chamber cover at the back, take out the filament spool, then pull the filament and thread it out from the filament sensor in the guide tube box.

6. Insert the desired filament (here, select ABS) into the reserved hole until filament is visible 3-5cm from the other end of the guide tube, then neatly arrange the filament spool (be careful not to tangle the filament) and place it on the spool holder. Close the filament chamber cover.

7. Click [ ![]() ], then select [L Extruder], select the filament to be loaded (here, select ABS), and click [Start].

], then select [L Extruder], select the filament to be loaded (here, select ABS), and click [Start].

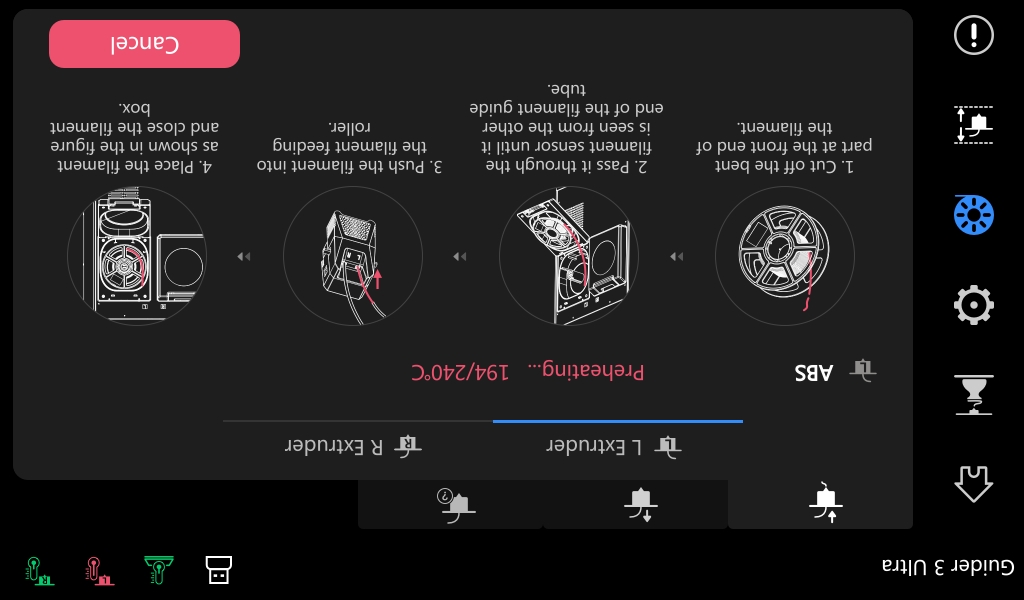

8. After clicking [Start], the printer starts heating up. The screen will display as shown below.

9. Once it reaches the target temperature and the printer displays loading is started, insert the filament from the upper inlet until it is firmly pulled into the printer. Then, release your hand.

10. Insert the guide tube into the inlet. Filament loading is completed when there is a large amount of filament flowing out of the nozzle. Wait for the printer to automatically stop.

11. If the printer completes extrusion but there is only a small amount or no filament flowing out of the nozzle, repeat steps 9-10 until a large amount of filament flows out of the nozzle.