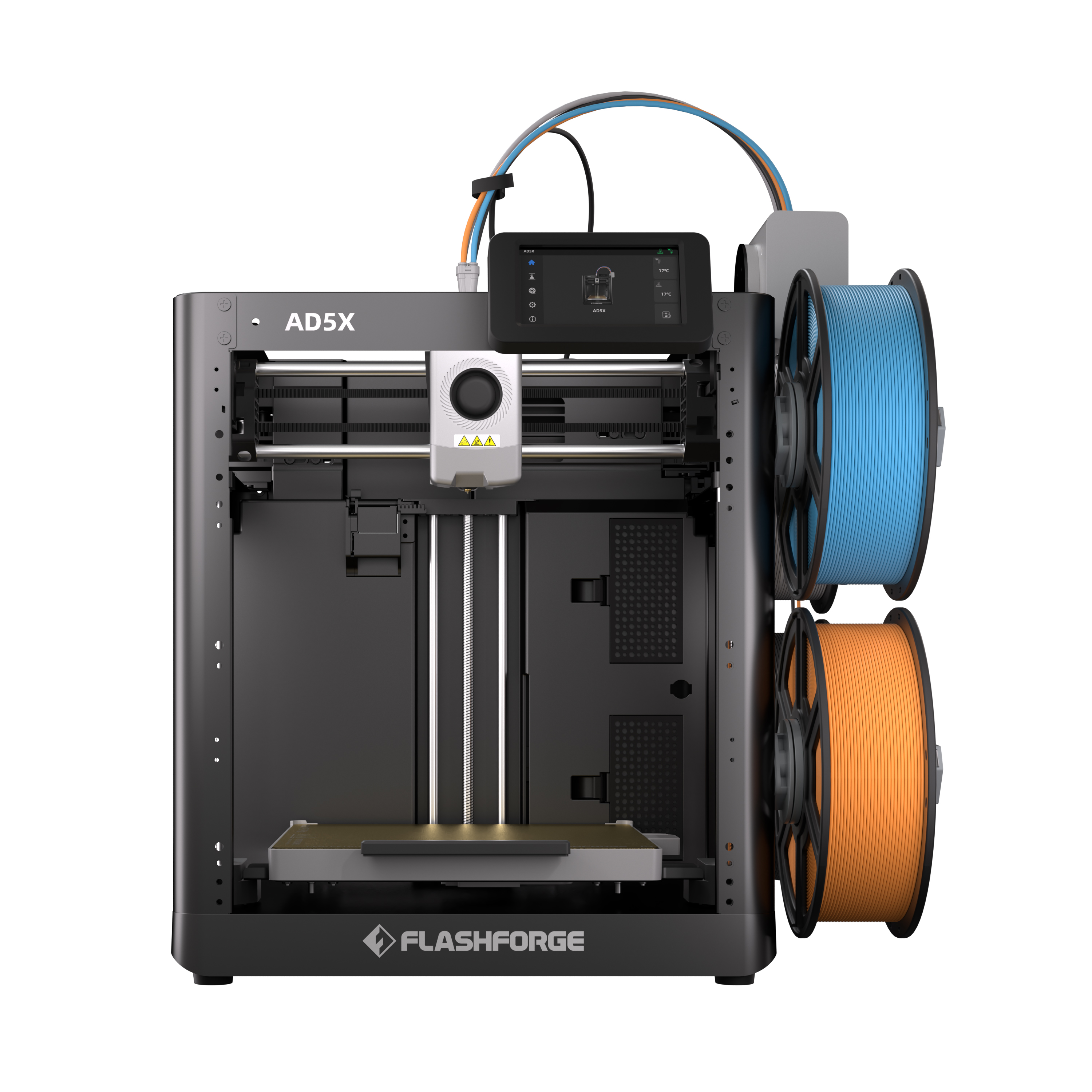

Built upon the successful Adventurer 5M, AD5X maintains its predecessor's automatic leveling, high print speed, rapid acceleration, and stable print quality. Additionally, it introduces two powerful new features: automatic filament refill and multi-color printing.

This document provides a basic overview of the mechanical structure and electrical components of AD5X for you to have a good grasp of AD5X.

¶ Working Principle of AD5X

AD5X is an FFF 3D printer that builds 3D objects by melting filament, extruding it from the nozzle, and depositing it layer by layer precisely.

For 3D printing, the most common type of model file is the STL format, which can be converted into a format recognized by 3D printers (such as 3MF or G-code) through the slicing software (e.g., Orca-Flashforge). These files contain instructions to precisely control where to move, how fast to move, what path to follow, and parameters like temperature and speed.

¶ CoreXY Structure

The CoreXY mechanism employs two motors working in unison to control the movement in both the X- and Y-axis. Movement along the X-axis occurs when both motors rotate in the same direction. Movement along the Y-axis occurs when both motors rotate in opposite directions. This design ensures precise and stable movement and allows for rapid acceleration.

The CoreXY structure offers several advantages over traditional 3D printer structures:

1. Less inertia. The motors in the CoreXY structure can move simultaneously, so it has much less inertia than other structures. This allows the extruder to be more stable when moving at high speeds, reducing vibration and wobble and improving print quality.

2. Higher speed and accuracy. With two motors moving simultaneously, the CoreXY structure can realize higher printing speed. Moreover, by accurately controlling the movement of both motors, higher printing accuracy can be realized, and more detailed models can be printed.

3. Smaller space occupation. The cross-over arrangement of the drive belts in the CoreXY structure results in a more compact path of motion for the extruder. The CoreXY configuration requires less space than other configurations and saves printer bed space.

4. Better stability and reliability. The two drive belts in the CoreXY structure intersect with each other to form a bi-directional tension balance, which effectively eliminates errors caused by inconsistencies in the belt tightening and loosening. This design not only improves the stability of printing, but also extends the life of the printer.

For more information about the CoreXY motion system, please visit this link.

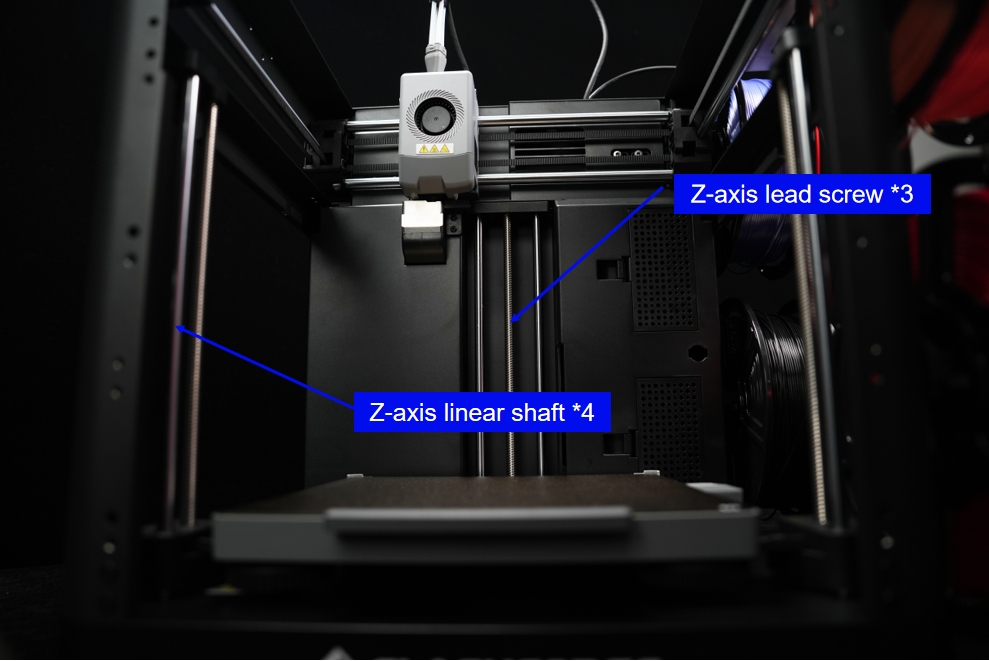

¶ Z-Axis

The Z-axis of AD5X is composed of three lead screws, which are connected to Z-axis stepper motors via belts.

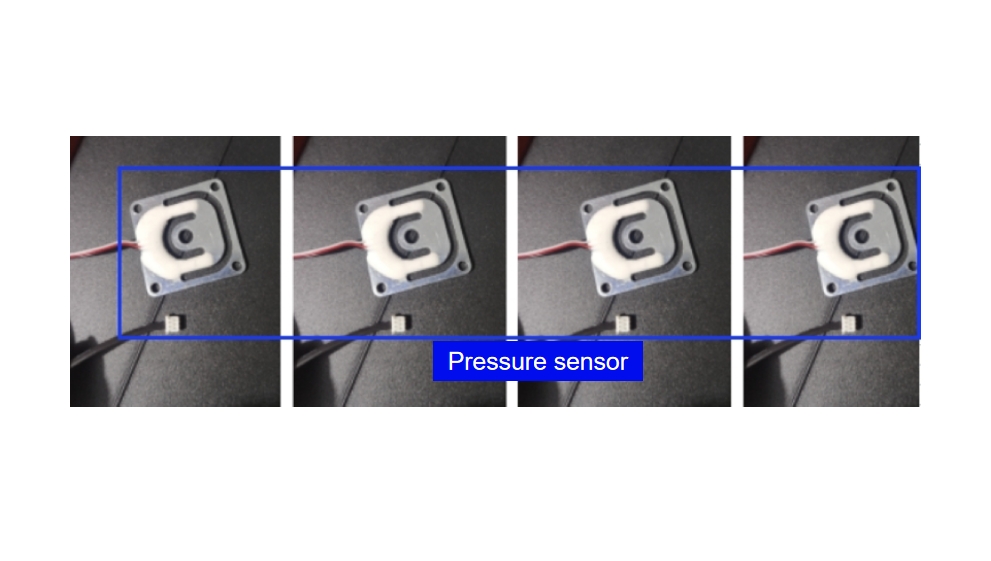

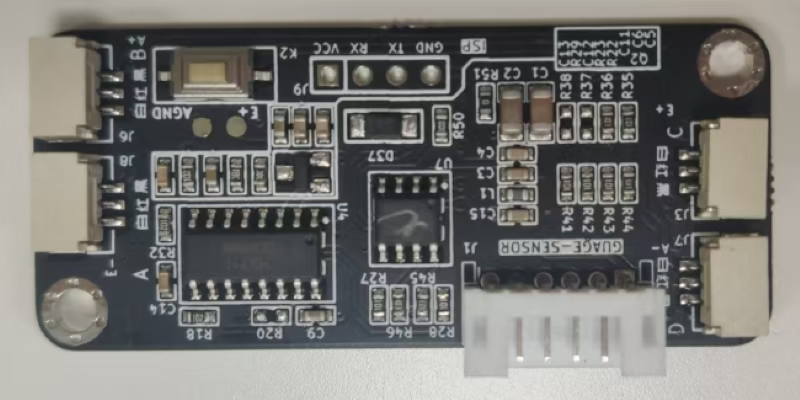

The heated bed has a pressure sensor at its base, enabling automatic Z-axis height calibration and leveling for a flawless first layer.

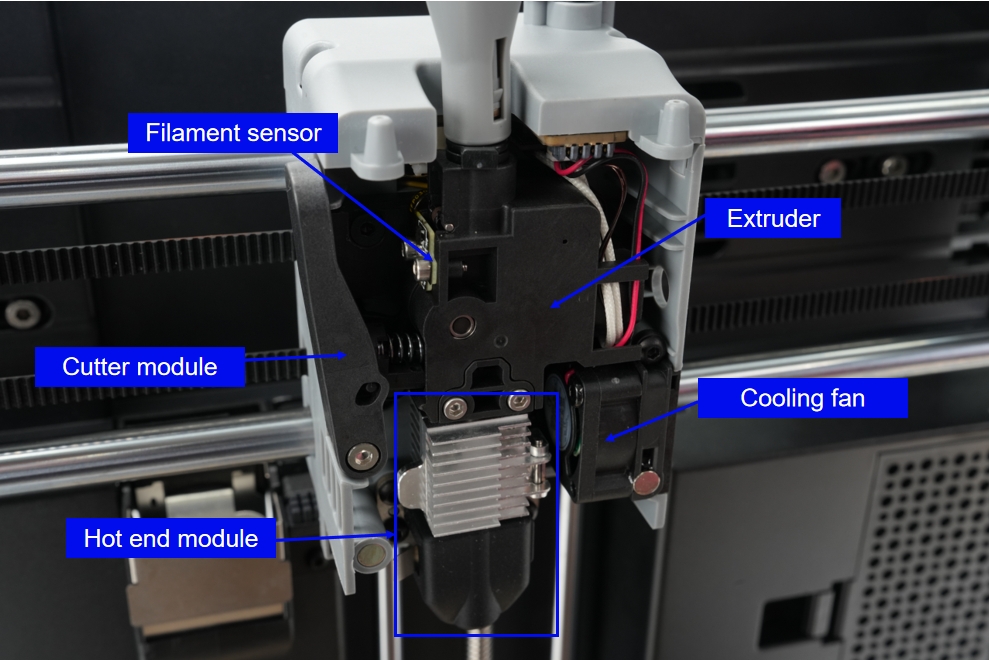

¶ Extruder

The extruder feeds filament to the hot end where it is then melted and extruded. Then 3D objects are created by layer-by-layer deposition of filaments.

1. The nozzle is tool-free removable.

2. The cooling fan prevents the filament from expanding and clogging the nozzle by cooling it at the heat break.

¶ Hot End

The hot end heats, melts, and extrudes the filament layer by layer.

¶ Heated Bed

The heated bed is crucial for the printed model, providing both support and adhesion to ensure a successful print. It is a 3D printer bed that can heat up to various temperatures. Within a suitable range, the higher its temperature, the stronger the bed adhesion, reducing the risk of warping. The AD5X's heated bed can heat up to 110°C.

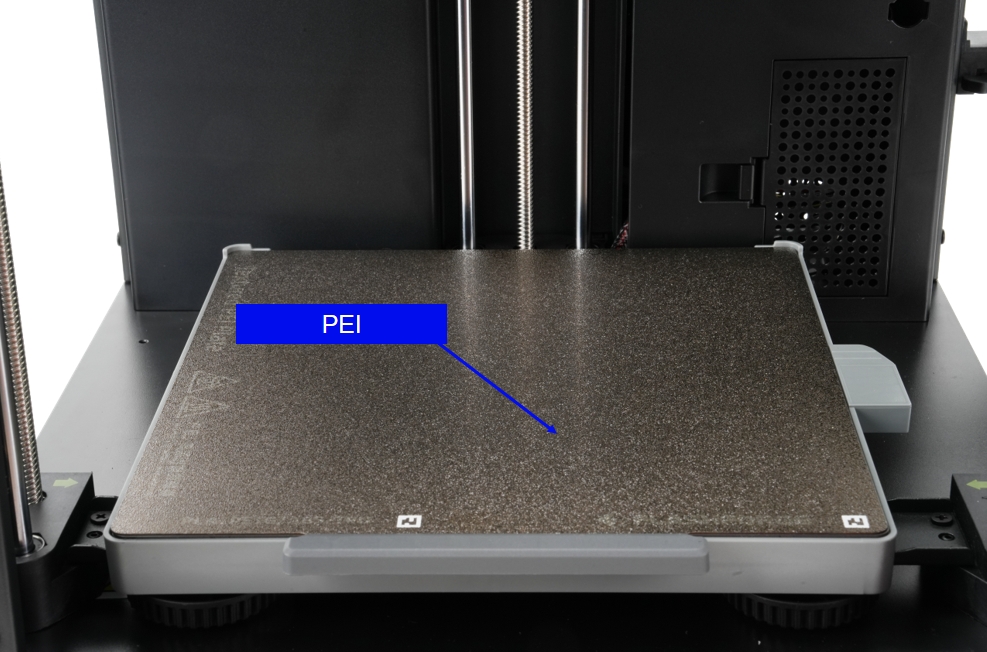

¶ Build Surface

AD5X is equipped with a flexible removable PEI steel sheet that can be used for printing filaments such as PLA, PETG, TPU, and more. Refer to this link for instructions on how to use the PEI sheet

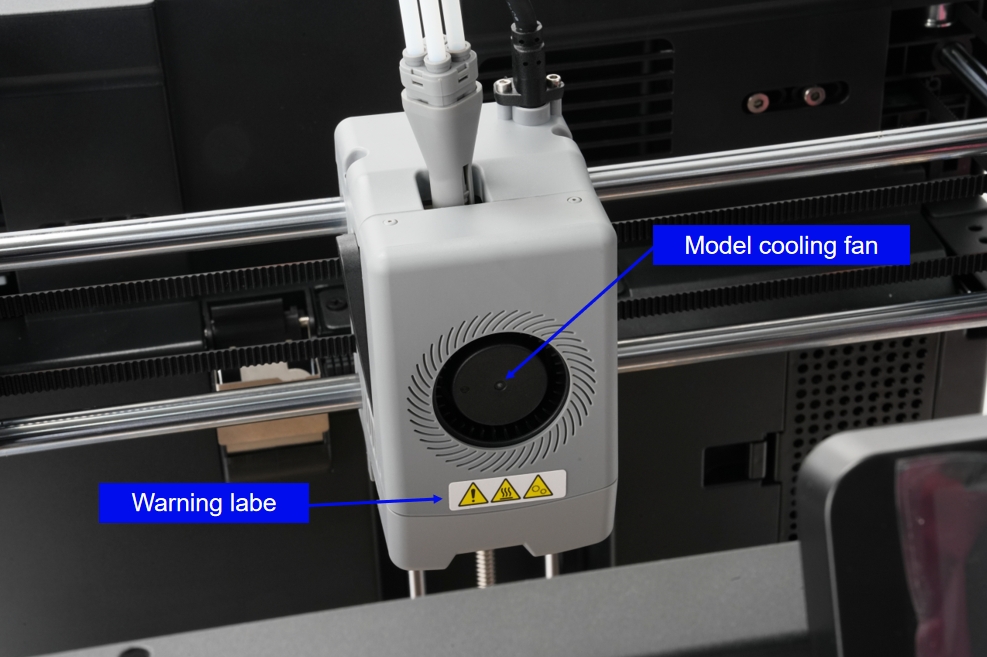

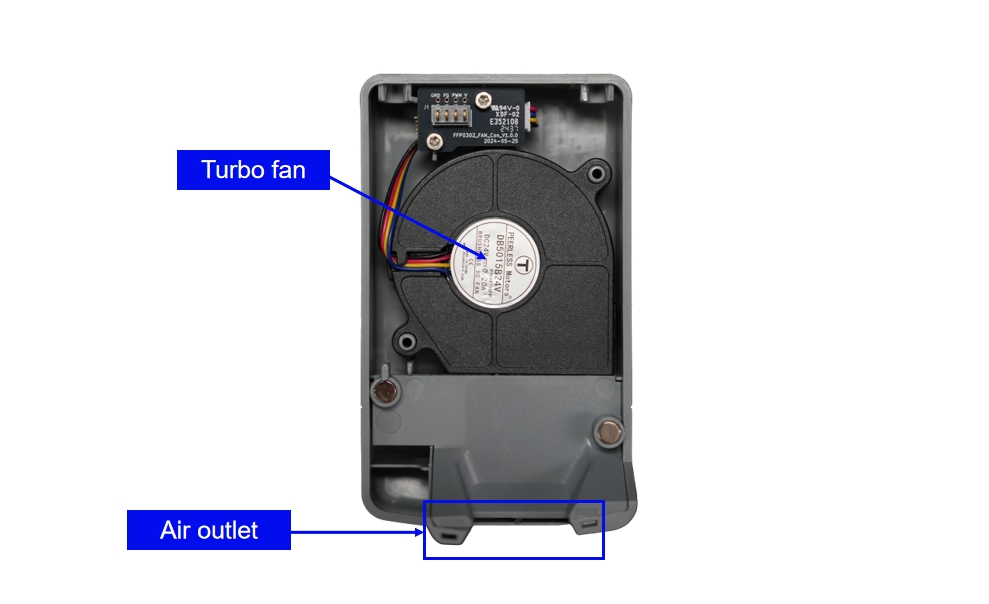

¶ Cooling System

AD5X is equipped with a model cooling fan, and the air ducts at both sides ensure comprehensive model cooling during the printing process.

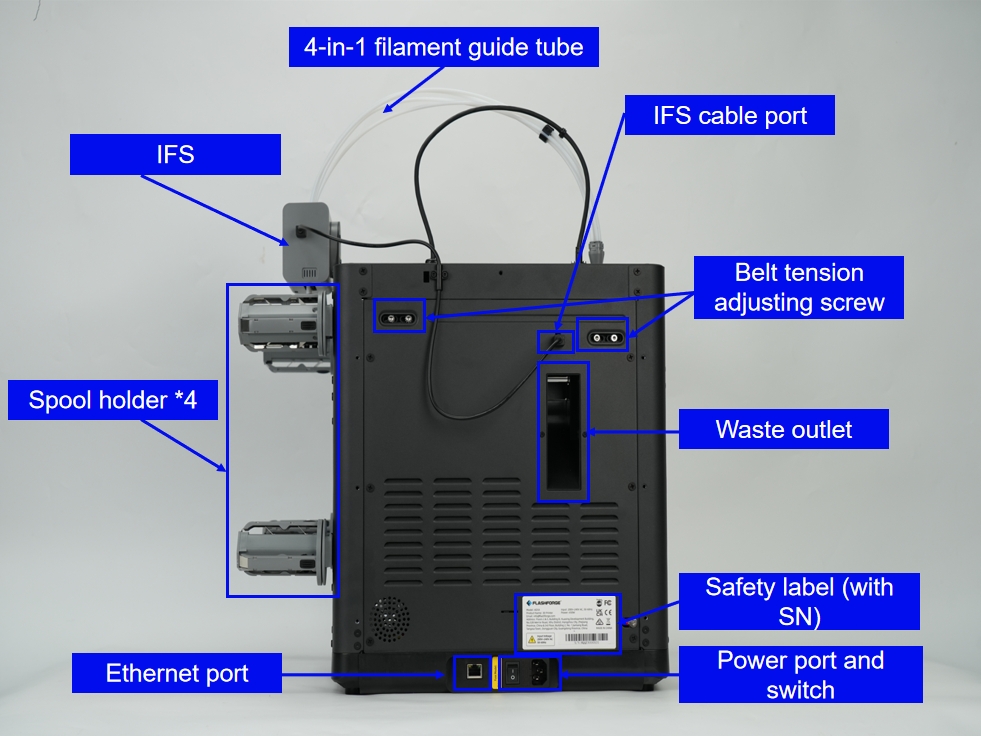

¶ Rear and Side of the Printer

Belt tension adjusting screw for adjusting the belt tension to an appropriate level;

Spool holder mounting holes for installing filament spool holders, offering convenient use.

¶ Electrical Components

AD5X features various electrical components. Here are just some key ones.

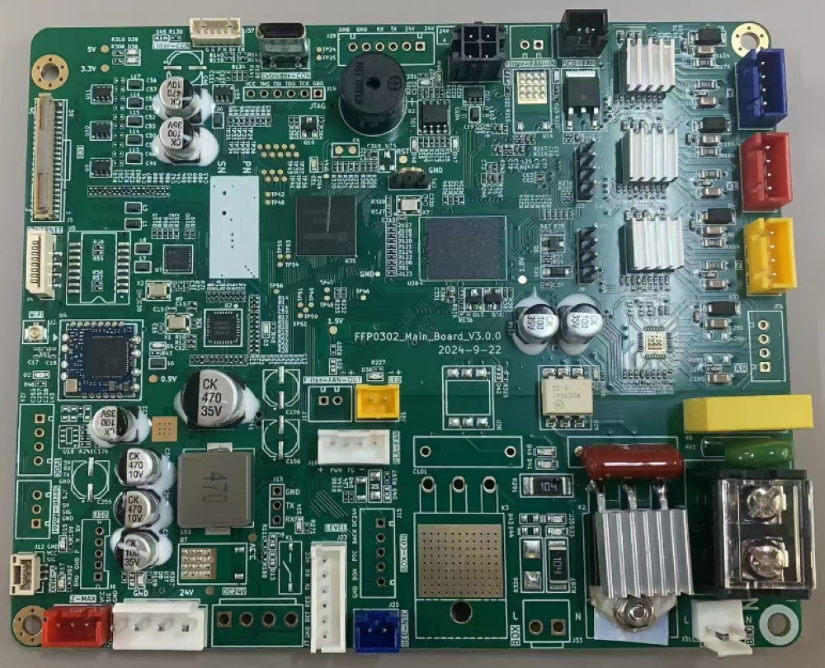

- Motherboard

The motherboard of AD5X uses a dual-core Cortex-A53 MCU, 8GB built-in storage, silent drivers, 5G & 2.4G Wi-Fi.

The firmware can enable functions like pressure compensation, automatic leveling, vibration compensation and extruder temperature calibration (PID calibration).

- Pressure Sensor

AD5X uses a one-click full-auto leveling system, measuring the relative height between the nozzle and the platform through the pressure sensing technology and performing automatic compensation. No need for leveling tools or manual Z-axis calibration, ensuring perfect first-layer quality.

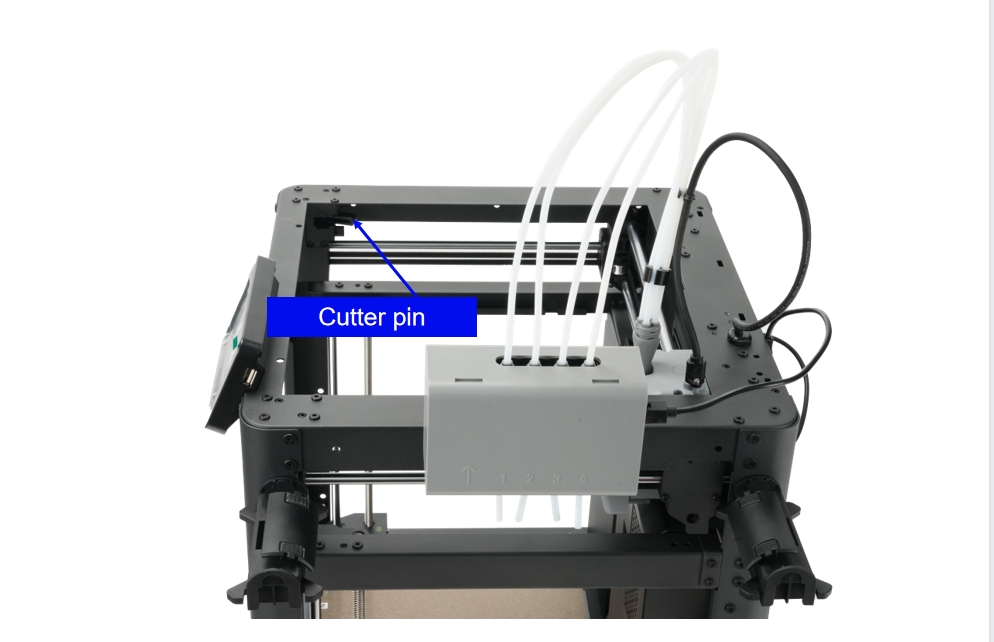

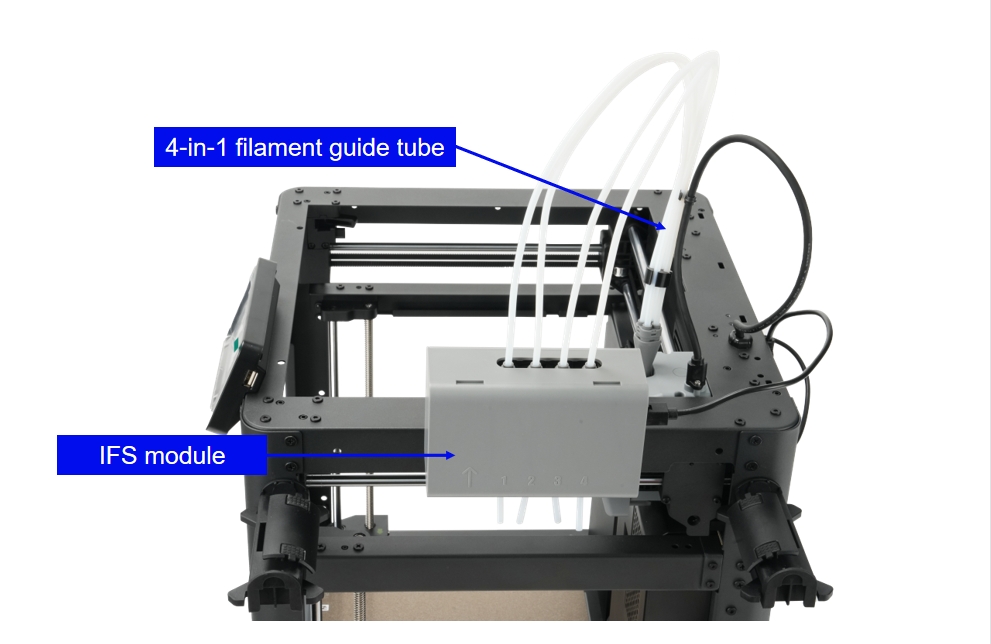

¶ IFS Module

AD5X is equipped with an automatic filament loading and unloading system to enable multi-color printing. This system primarily consists of two 28 stepper motors, a clutch shaft, and four filament channels, allowing for automatic channel switching and filament feeding.