1. On the main interface, click [![]() ] to enter the filament interface.

] to enter the filament interface.

2. Select the channel for the filament you want to replace. For example, select Channel 1 on the filament interface and then click [![]() ].

].

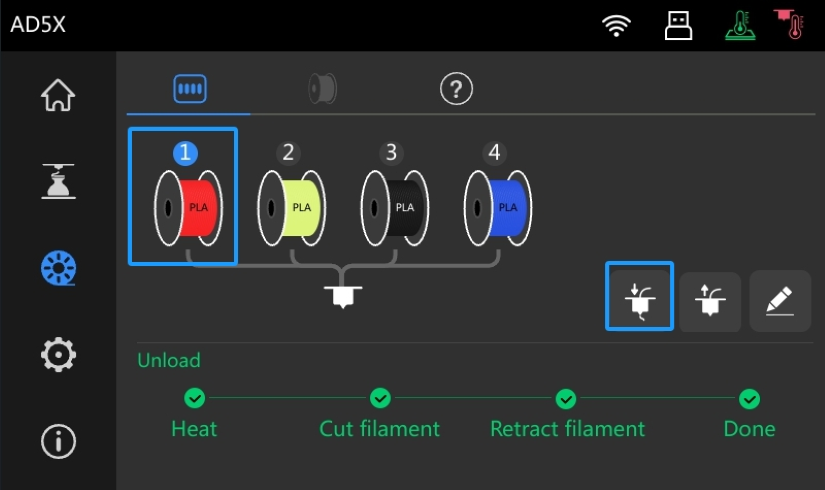

3. Then, the printer will start filament unloading, as shown below.

4. It will then heat the extruder, cut the filament, and retract the filament. Once these steps are completed, the filament unloading process is finished, as shown below.

5. Remove the retracted filament from the spool holder and install the new filament onto the spool holder.

6. Insert the filament into the IFS module until the screen displays "Filament auto-loading, please wait..."

7. Once "Filament auto-loading, please wait..." appears on the screen, you can remove your hand. IFS module will automatically load the filament into the 4-in-1 guide tube. The automatic loading process will end when the filament reaches the preset position.

8. Click [![]() ].

].

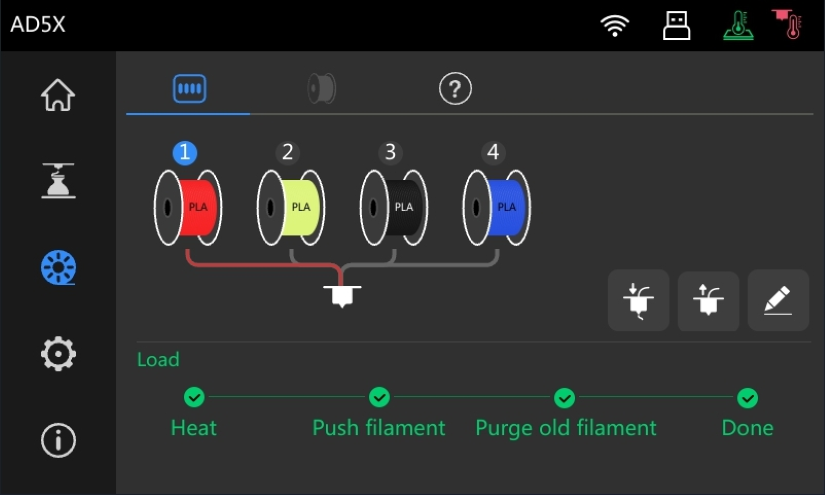

9. Then, the printer will start automatic filament loading, as shown below.

10. It will then heat the extruder, push the filament, and purge any remaining old filament. Once these steps are completed, the filament loading process is finished, as shown below.

Note:

1. When switching from a high-temperature material to a low-temperature material, such as switching from ABS to PLA, a cleaning action is required. After inserting the PLA filament, please load it 1-2 times at the ABS filament loading temperature.

2. When printing with PETG, due to its sticky property, a cleaning operation on the extruder is necessary when changing filament.