During printing, long-term high temperatures can cause filament residue to carbonize and stick to the inside walls of the nozzle, or poor-quality filament containing impurities may clog the nozzle. This results in inconsistent extrusion or a complete clog. A "cold pull" is a proven, effective, and practical method for cleaning out these internal impurities. Here is a guide on how to perform a cold pull on your AD5X.

1.Remove the front cover of the extruder assembly;

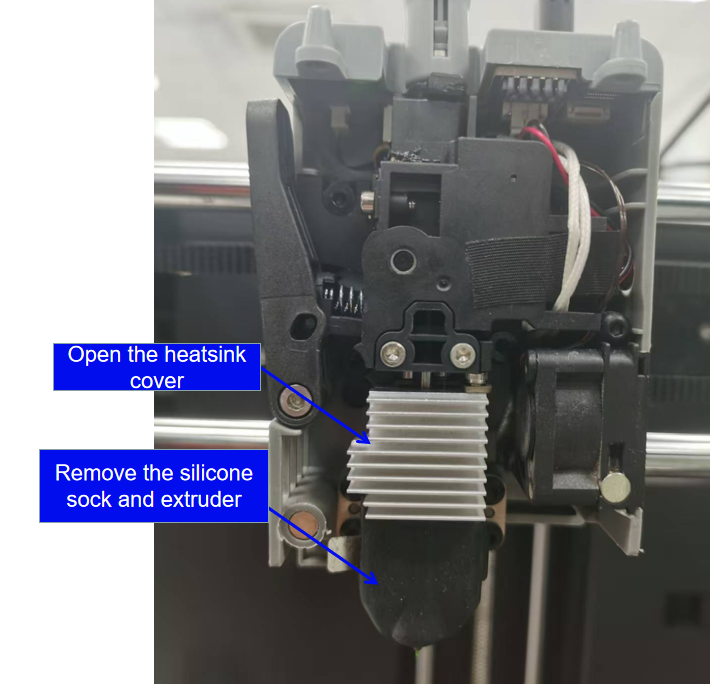

2.Remove the silicone sock, open the heatsink cover, and detach the extruder assembly from the hotend;

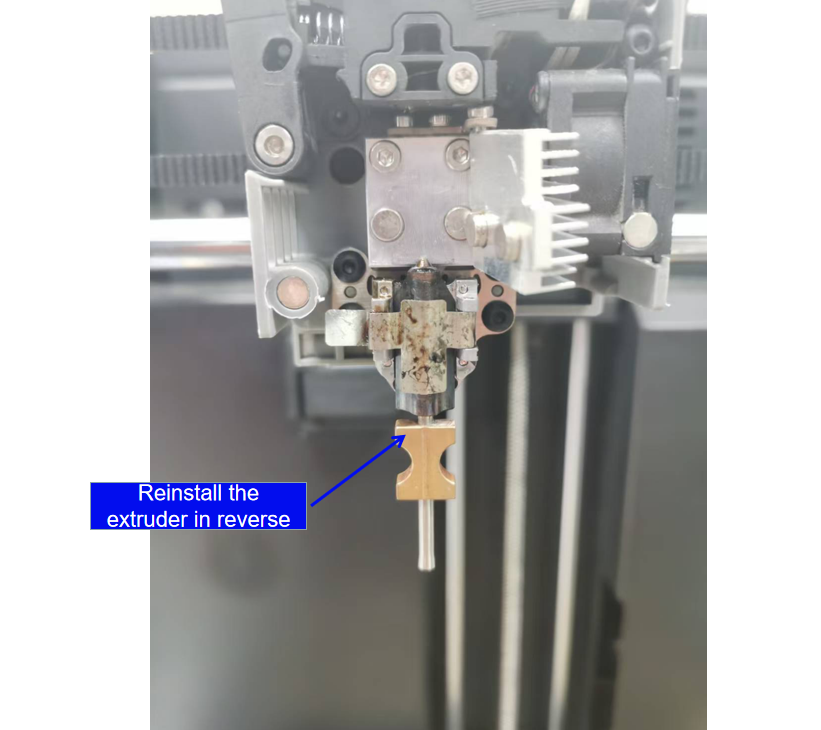

- As shown in the image, reinstall the extruder in reverse onto the hotend and secure the latch;

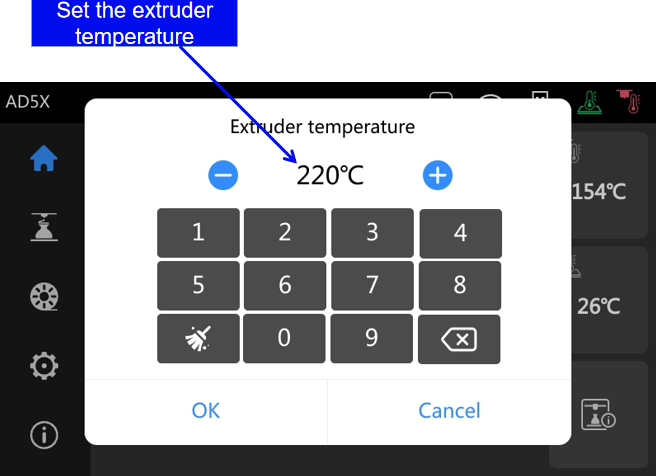

4.Set the extruder temperature to 220°C (if manual filament feeding feels difficult, you may increase the temperature to 250°C);

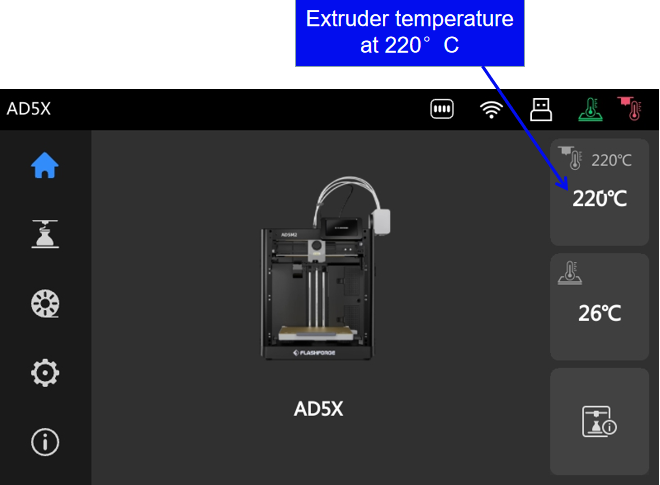

5.Check the extruder temperature;

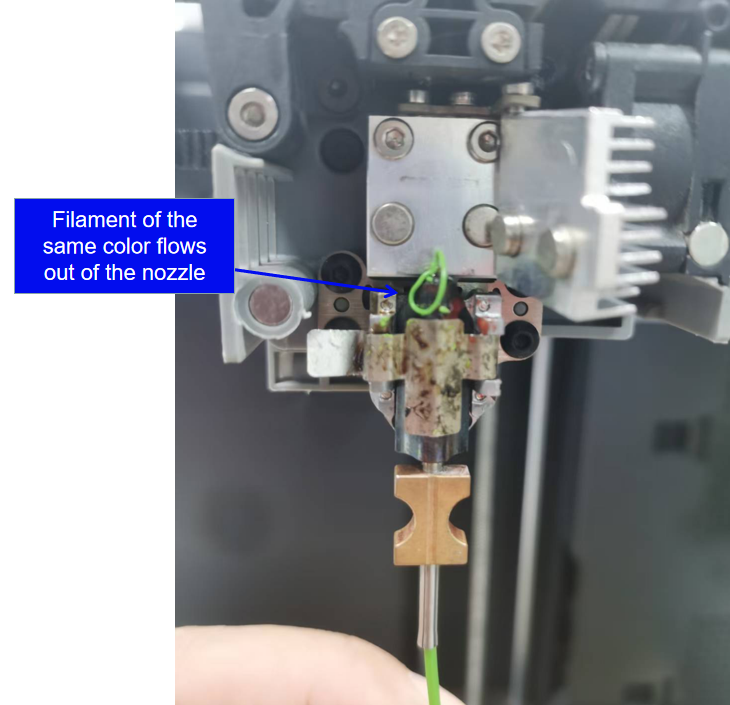

6.Once the extruder reaches 220°C, insert PLA filament manually and push it upward until you see filament being extruded from the nozzle. Then, stop pushing;

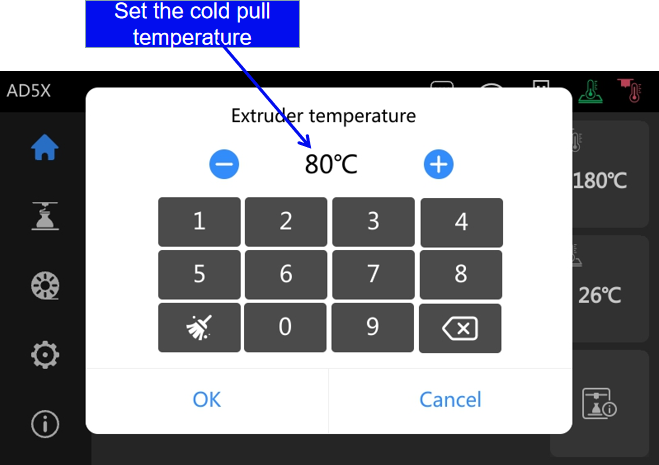

7.Set the cold pull temperature to 80°C;

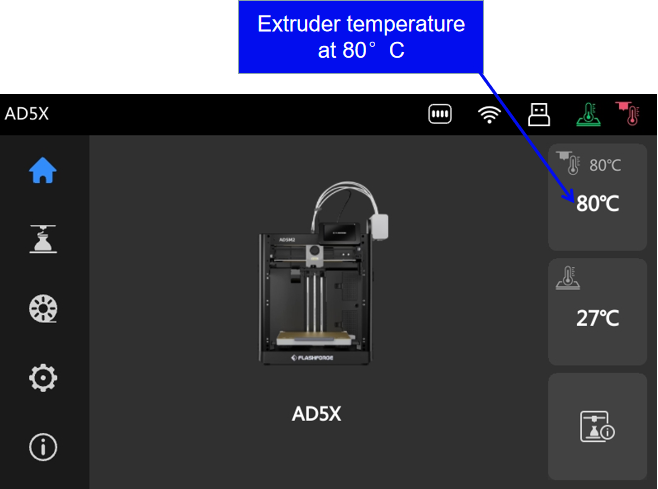

8.Confirm that the nozzle temperature has dropped to 80°C;

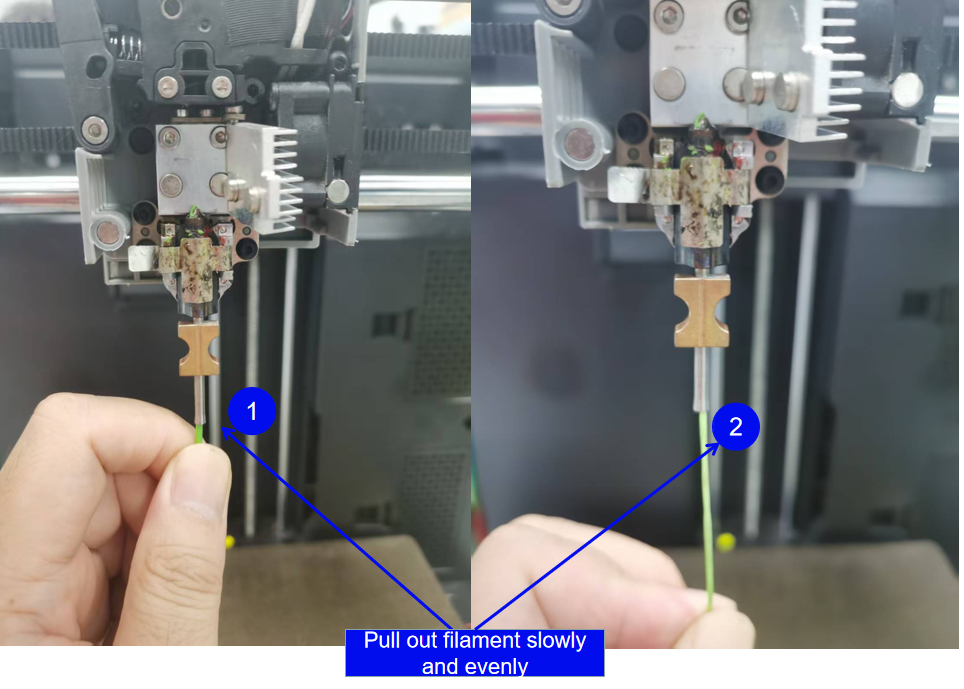

9.After the nozzle has cooled to 80°C, hold the filament and slowly, evenly pull it out;

Cold Pull Video Guide(Click to watch):

Cold Pull Video.mp4

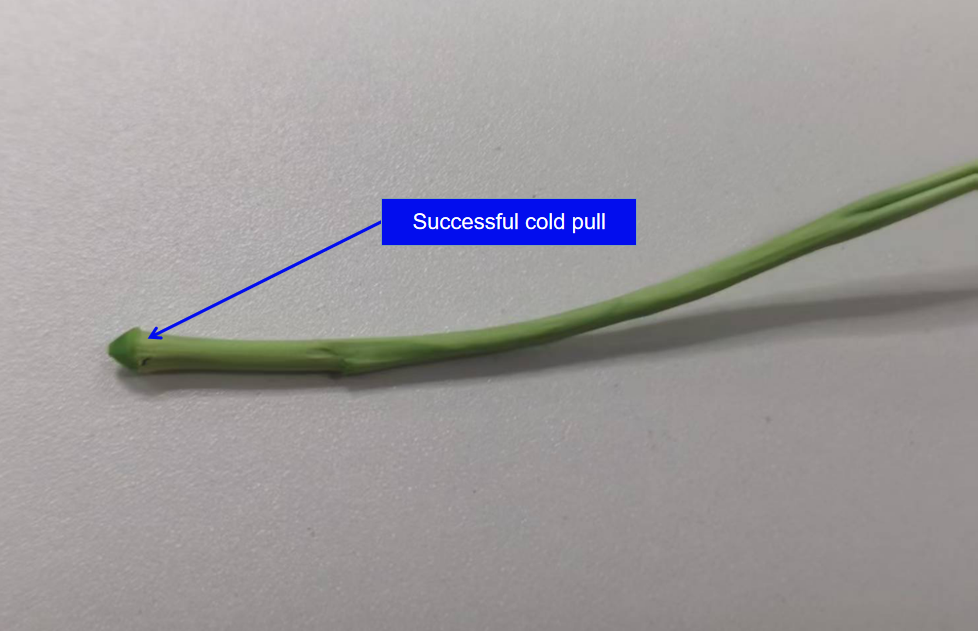

10.After a successful cold pull, the filament should look as shown below;

If the filament breaks during the process causing the cold pull to fail, repeat Steps 5-10. To fully clear out debris, you may repeat the cold pull multiple times.

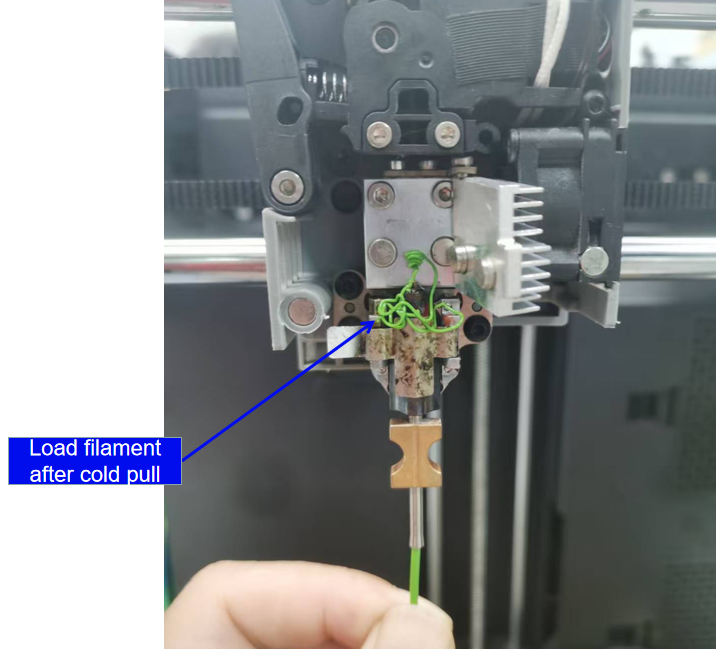

- To confirm the nozzle is clean, heat the extruder up to 220°C. You should be able to manually feed the filament with ease, and it should flow continuously from the nozzle, indicating that the clog has been cleared.

Cold Pull Video Guide(Click to watch):

Filament Loading Video.mp4